Automating your factory or workshop’s sheet metal production can be a wise investment. Not only are costs of maintaining a skilled workforce increasing, modern industry demands often require small batches to be produced rapidly and to a high standard.

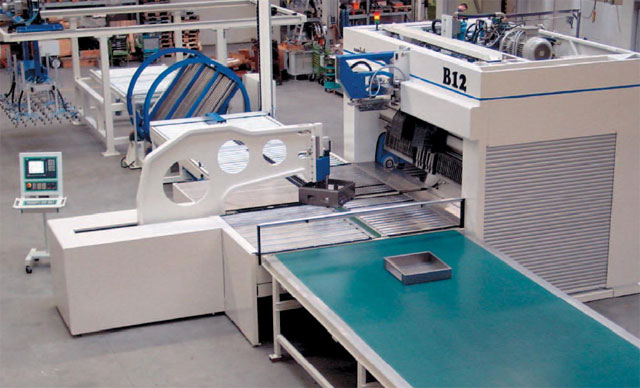

Ron Mack Machinery is proud to introduce the B12 Bending Centre from Weinbrenner. Fully automatic, the machine offers rapid processing of punched or laser cut sheet metal components up to 3mm in thickness.

With systems to optimise workflow, the swing bending action offers a range of advantages with two independently operated jaws that allows for virtually unlimited rearward bending space. In addition, this method does not damage the surface of the fabricated components.

The B12 is available to process a range of standard size stock in lengths from 2,160 up to 5,160mm for 2mm thick sheet and up to 4,060mm for 3mm sheet. A range of flange heights are offered from 160 up to 350mm for 2mm sheet and 300mm for 3mm sheet.

To further improve productivity the system can be integrated to work with automated CNC Turret Presses and Laser Cutting Systems allowing the workshop to be staffed by just a few semi-skilled operators. Conveyor systems and robotic arms can also be implemented to further automate the workflow.

For further information, view the Specifications here or call 1800 818 448